【Product】Centrifugal separator&Chip Removal machine

Features

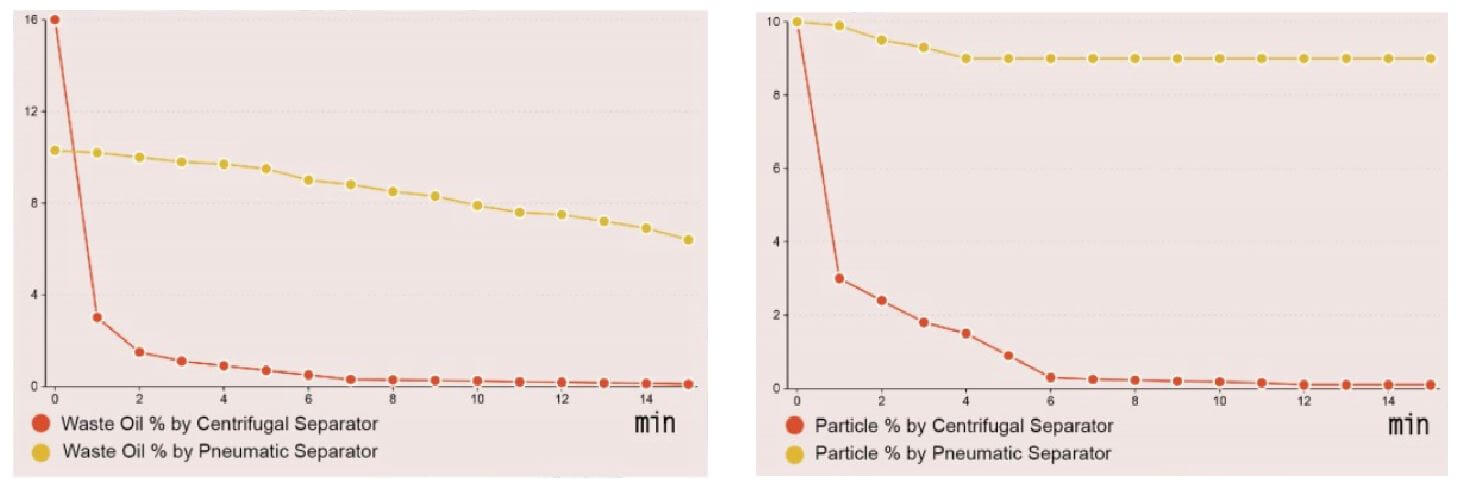

- Filter impurities and particles, and the filtration precision can reach up to 5-10μm.

- Process up to 15 liters of cutting fluid per minute to remove waste oil, emulsions, and impurities.

- With centrifugal approach, no need to wait for tramp oil-water sepration by gravity.

- Increase oxygen content in water to prevent anaerobic bacteria growth.

- Good mobility, one can meet the needs of the whole factory.

- Significantly reduce the amount of wastewater, save the consumption of cutting fluids.

- No consumable filter.

Specification

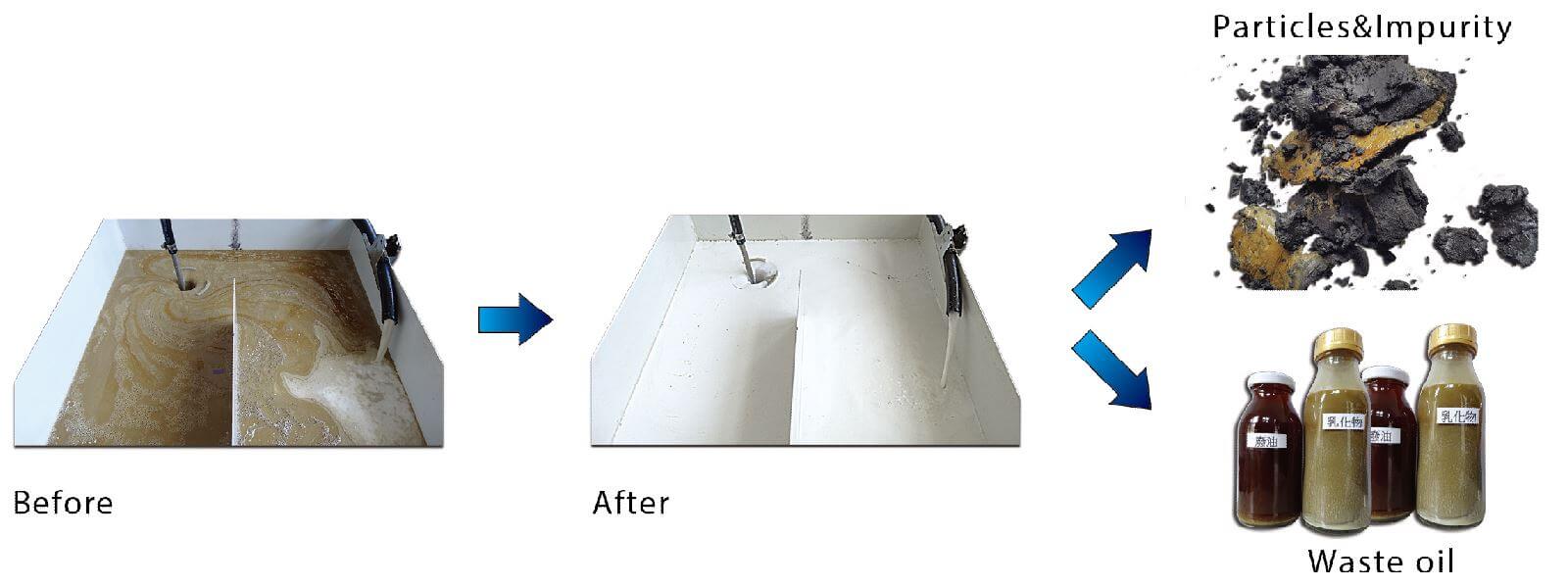

Processing flow

The use of this high efficiency centrifugal separator can effectively extend the oil change period and prolong the lifetime of cutting fluid, promote machining accuracy. It also improves the deterioration and stink of cutting fluid, Reduce environmental pollution and health problems of the operator, as well as improve the working efficiency and save costs.

【Product】Chip Removal machine

Features

1. No need to shut down for quick processing and you can easily solve the problems of dusty chip deposition.

2. Can be used for water-based and oil-based cutting fluids, metal cuttings, aluminum powders, and non-magentic metal particles.

3. Surface floating debris, bottom fine chips, bottom sediment and other deposits can be quickly processed and recycled.

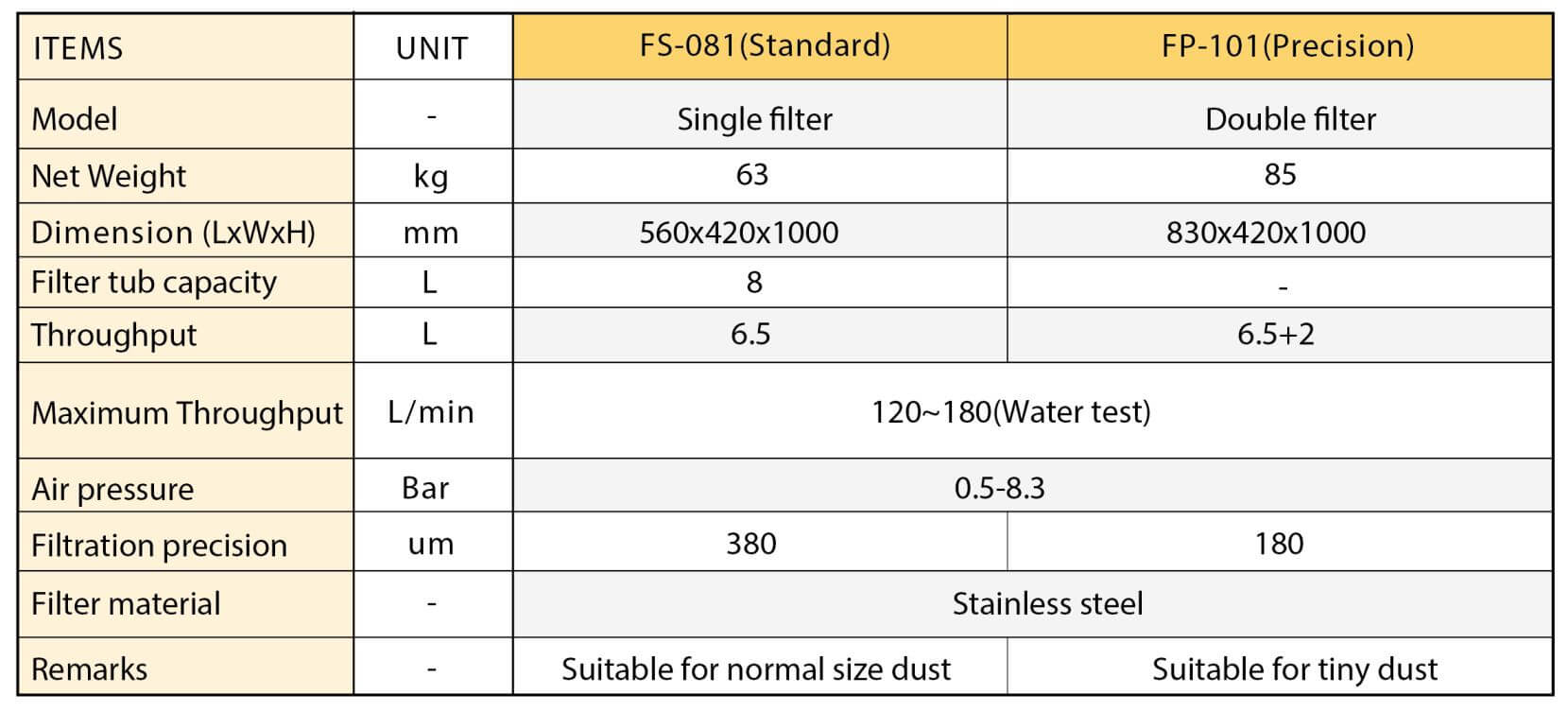

4. Effectively save the time and cost of cleaning the water tank. The double filtration (optional-precision type) grinding powder can be easily recycled.

5. Easy to move and can be used on one or more platforms.

6. Can be adjusted to different filter accuracy requirements.

Specification

Processing flow